Why Silver

Why silver:

This Movie Discuss the different between Silver 999 and Silver 925:

The two distinct levels of purity when it comes to silver are the silver 999 and less pure 925. Let's dive deeper into the comparison between these two types of silver:

Composition and Purity:

Silver 999: Also known as "fine silver," Silver 999 is composed of 99.9% pure silver, with minimal impurities. This high level of purity gives it a bright white color and exceptional shine. Fine silver is the closest to pure elemental silver and is famous for its Shine and beauty.

However Silver 925or "sterling silver," is an alloy containing 92.5% pure silver and 7.5% other metals, typically copper

Appearance:

Silver 999 has a strikingly bright and white appearance due to its high purity. It reflects light beautifully and is often used in exquisite jewelry and artistic creations.

Silver 925 has a slightly softer, louder color compared to fine silver. It may also develop a color over time due to the presence of other metals.

Value:

Silver 999 is generally considered more valuable than Silver 925 due to its higher purity. It is often used for investment purposes in the form of bullion coins and bars.

The preferred coin, rounds and bars are Silver 999 which boasts unparalleled purity, artistic qualities and value. We at Freedom mint preferred silver is 999 silver rounds, coins and bars.

What is Silver:

Silver is a chemical element with the symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. The metal is found in the Earth's crust in the pure, free elemental form ("native silver"), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc refining.

Silver has long been valued as a precious metal. Silver metal is used in many bullion coins, sometimes alongside gold: while it is more abundant than gold, it is much less abundant as a native metal. Its purity is typically measured on a per-mile basis; a 94%-pure alloy is described as "0.940 fine". As one of the seven metals of antiquity, silver has had an enduring role in most human cultures.Other than in currency and as an investment medium (coins and bullion), silver is used in solar panels, water filtration, jewelry, ornaments, high-value tableware and utensils (hence the term silverware), in electrical contacts and conductors, in specialized mirrors, window coatings, in catalysis of chemical reactions, as a colorant in stained glass and in specialized confectionery. Its compounds are used in photographic and X-ray film. Dilute solutions of silver nitrate and other silver compounds are used as disinfectants and microbiocides (oligodynamic effect), added to bandages and wound-dressings, catheters, and other medical instruments.

The History of Silver:

Silver was one of the seven metals of antiquity that were known to prehistoric humans and whose discovery is thus lost to history. In particular, the three metals of group 11, copper, silver, and gold, occur in the elemental form in nature and were probably used as the first primitive forms of money as opposed to simple bartering. However, unlike copper, silver did not lead to the growth of metallurgy on account of its low structural strength, and was more often used ornamentally or as money.[54] Since silver is more reactive than gold, supplies of native silver were much more limited than those of gold. For example, silver was more expensive than gold in Egypt until around the fifteenth century BC: the Egyptians are thought to have separated gold from silver by heating the metals with salt, and then reducing the silver chloride produced to the metal. The situation changed with the discovery of cupellation, a technique that allowed silver metal to be extracted from its ores. While slag heaps found in Asia Minor and on the islands of the Aegean Sea indicate that silver was being separated from lead as early as the 4th millennium BC,and one of the earliest silver extraction centers in Europe was Sardinia in the early Chalcolithic period, these techniques did not spread widely until later, when it spread throughout the region and beyond.[55] The origins of silver production in India, China, and Japan were almost certainly equally ancient, but are not well-documented due to their great age. Silver mining and processing in Kutná Hora, Bohemia, 1490s When the Phoenicians first came to what is now Spain, they obtained so much silver that they could not fit it all on their ships, and as a result used silver to weight their anchors instead of lead.[55] By the time of the Greek and Roman civilizations, silver coins were a staple of the economy: the Greeks were already extracting silver from galena by the 7th century BC,and the rise of Athens was partly made possible by the nearby silver mines at Laurium, from which they extracted about 30 tonnes a year from 600 to 300 BC.[58] The stability of the Roman currency relied to a high degree on the supply of silver bullion, mostly from Spain, which Roman miners produced on a scale unparalleled before the discovery of the New World. Reaching a peak production of 200 tonnes per year, an estimated silver stock of 10000 tonnes circulated in the Roman economy in the middle of the second century AD, five to ten times larger than the combined amount of silver available to medieval Europe and the Abbasid Caliphate around AD 800.[59][60] The Romans also recorded the extraction of silver in central and northern Europe in the same time period. This production came to a nearly complete halt with the fall of the Roman Empire, not to resume until the time of Charlemagne: by then, tens of thousands of tonnes of silver had already been extracted.Central Europe became the centre of silver production during the Middle Ages, as the Mediterranean deposits exploited by the ancient civilisations had been exhausted. Silver mines were opened in Bohemia, Saxony, Erzgebirge, Alsace, the Lahn region, Siegerland, Silesia, Hungary, Norway, Steiermark, Salzburg, and the southern Black Forest. Most of these ores were quite rich in silver and could simply be separated by hand from the remaining rock and then smelted; some deposits of native silver were also encountered. Many of these mines were soon exhausted, but a few of them remained active until the Industrial Revolution, before which the world production of silver was around a meagre 50 tonnes per year.In the Americas, high temperature silver-lead cupellation technology was developed by pre-Inca civilizations as early as AD 60–120; silver deposits in India, China, Japan, and pre-Columbian America continued to be mined during this time.With the discovery of America and the plundering of silver by the Spanish conquistadors, Central and South America became the dominant producers of silver until around the beginning of the 18th century, particularly Peru, Bolivia, Chile, and Argentina:the last of these countries later took its name from that of the metal that composed so much of its mineral wealth.The silver trade gave way to a global network of exchange. As one historian put it, silver "went round the world and made the world go round." Much of this silver ended up in the hands of the Chinese. A Portuguese merchant in 1621 noted that silver "wanders throughout all the world... before flocking to China, where it remains as if at its natural center."[63] Still, much of it went to Spain, allowing Spanish rulers to pursue military and political ambitions in both Europe and the Americas. "New World mines," concluded several historians, "supported the Spanish empire."In the 19th century, primary production of silver moved to North America, particularly Canada, Mexico, and Nevada in the United States: some secondary production from lead and zinc ores also took place in Europe, and deposits in Siberia and the Russian Far East as well as in Australia were mined.[56] Poland emerged as an important producer during the 1970s after the discovery of copper deposits that were rich in silver, before the center of production returned to the Americas the following decade. Today, Peru and Mexico are still among the primary silver producers, but the distribution of silver production around the world is quite balanced and about one-fifth of the silver supply comes from recycling instead of new production.

Monetary Use of silver:

The earliest known coins were minted in the kingdom of Lydia in Asia Minor around 600 BC.[82] The coins of Lydia were made of electrum, which is a naturally occurring alloy of gold and silver, that was available within the territory of Lydia.[82] Since that time, silver standards, in which the standard economic unit of account is a fixed weight of silver, have been widespread throughout the world until the 20th century. Notable silver coins through the centuries include the Greek drachma,[83] the Roman denarius,[84] the Islamic dirham,the karshapana from ancient India and rupee from the time of the Mughal Empire (grouped with copper and gold coins to create a trimetallic standard),and the Spanish dollar.The ratio between the amount of silver used for coinage and that used for other purposes has fluctuated greatly over time; for example, in wartime, more silver tends to have been used for coinage to finance the war.Today, silver bullion has the ISO 4217 currency code XAG, one of only four precious metals to have one (the others being palladium, platinum, and gold). Silver coins are produced from cast rods or ingots, rolled to the correct thickness, heat-treated, and then used to cut blanks from. These blanks are then milled and minted in a coining press; modern coining presses can produce 8000 silver coins per hour.

Jewelry and silverware:

The major use of silver besides coinage throughout most of history was in the manufacture of jewelry and other general-use items, and this continues to be a major use today. Examples include table silver for cutlery, for which silver is highly suited due to its antibacterial properties. Western concert flutes are usually plated with or made out of sterling silver;in fact, most silverware is only silver-plated rather than made out of pure silver; the silver is normally put in place by electroplating. Silver-plated glass (as opposed to metal) is used for mirrors, vacuum flasks, and Christmas tree decorations Because pure silver is very soft, most silver used for these purposes is alloyed with copper, with finenesses of 925/1000, 835/1000, and 800/1000 being common. One drawback is the easy tarnishing of silver in the presence of hydrogen sulfide and its derivatives. Including precious metals such as palladium, platinum, and gold gives resistance to tarnishing but is quite costly; base metals like zinc, cadmium, silicon, and germanium do not totally prevent corrosion and tend to affect the lustre and color of the alloy. Electrolytic-ally refined pure silver plating is effective at increasing resistance to tarnishing. The usual solutions for restoring the lustre of tarnished silver are dipping baths that reduce the silver sulfide surface to metallic silver, and cleaning off the layer of tarnish with a paste; the latter approach also has the welcome side effect of polishing the silver concurrently.[94] A simple chemical approach to removal of the sulfide tarnish is to bring silver items into contact with aluminium foil whilst immersed in water containing a conducting salt, such as sodium chloride.

Silver and medicine:

In medicine, silver is incorporated into wound dressings and used as an antibiotic coating in medical devices. Wound dressings containing silver sulfadiazine or silver nano materials are used to treat external infections. Silver is also used in some medical applications, such as urinary catheters (where tentative evidence indicates it reduces catheter-related urinary tract infections) and in endotracheal breathing tubes (where evidence suggests it reduces ventilator-associated pneumonia).The silver ion is bio-active and in sufficient concentration readily kills bacteria in vitro. Silver ions interfere with enzymes in the bacteria that transport nutrients, form structures, and synthesis cell walls; these ions also bond with the bacteria's genetic material. Silver and silver nano particles are used as an antimicrobial in a variety of industrial, healthcare, and domestic application: for example, infusing clothing with nano-silver particles thus allows them to stay odorless for longer.Bacteria can, however, develop resistance to the antimicrobial action of silver.Silver compounds are taken up by the body like mercury compounds, but lack the toxicity of the latter. Silver and its alloys are used in cranial surgery to replace bone, and silver–tin–mercury amalgams are used in dentistry.[95] Silver diam-mine fluoride, the fluoride salt of a coordination complex with the formula [Ag(NH3)2]F, is a topical medicament (drug) used to treat and prevent dental caries (cavities) and relieve dentinal hypersensitivity.

Silver in Electronics:

Silver is very important in electronics for conductors and electrodes on account of its high electrical conductivity even when tarnished. Bulk silver and silver foils were used to make vacuum tubes, and continue to be used today in the manufacture of semiconductor devices, circuits, and their components. For example, silver is used in high quality connectors for RF, VHF, and higher frequencies, particularly in tuned circuits such as cavity filters where conductors cannot be scaled by more than 6%. Printed circuits and RFID antennas are made with silver paints,[7][102] Powdered silver and its alloys are used in paste preparations for conductor layers and electrodes, ceramic capacitors, and other ceramic components

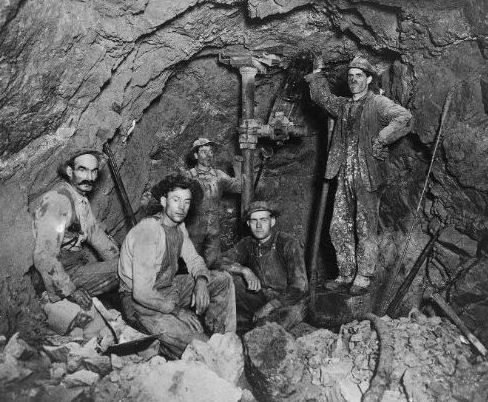

SILVER MINING IN HISTORY

The story of silver mining began about 5,000 years ago.

Silver was first mined around 3,000 BCE in Anatolia, now located in modern-day Turkey. The precious metal helped early civilizations in the Near East, Ancient Greece to flourish.

In about 1,200 BCE the center of silver production shifted to Greece’s Laurium mines, where it continued to feed the region’s growing empires, even providing currency for ancient Athens. By about 100 CE, the center of silver mining moved to Spain, where the mines became a major supplier for the Roman Empire and an essential trading component along the Asian spice routes.

However, no other single event in silver’s history rivals the discovery by European conquerors of the white metal in the Americas following Columbus’s landing in the New World in 1492. The events that unfolded in the following years changed the face of silver and the world forever.

The Spanish conquest of the Americas led to an increase in the mining of silver that dramatically eclipsed anything that had come before that time. Between 1500 and 1800, Bolivia, Peru and Mexico accounted for over 85 percent of world silver production and trade as it bolstered Spanish influence in the New World and elsewhere.

Later, mining spread to other countries, most notably the United States with the discovery of the Comstock Lode in Nevada. Silver production continued to expand worldwide, growing from 40 to 80 million ounces annually by the 1870s. The period from 1876 to 1920 witnessed an explosion in both technological innovation and exploitation of new regions worldwide. Production over the last quarter of the 19th century quadrupled over the average of the first 75 years to a total of nearly 120 million ounces annually.

New silver discoveries in Australia, Central America and Europe added to total world silver production. The twenty years between 1900 and 1920 resulted in a 50 % increase in global production, and brought the total to about 190 million ounces annually. These increases were spurred by new discoveries in Canada, the United States, Africa, Mexico, Chile, Japan, and elsewhere. During the 1900s, new mining techniques contributed to a massive rise in overall silver production. Breakthroughs included steam-assisted drilling, mine dewatering, and improved haulage. Further, advances in mining techniques enhanced the ability to separate silver from other ores and made it possible to handle larger volumes of material. These new methods were critical to the increased volume of production, as many of the high-grade ores throughout the world had been largely used up by the end of the 19th century.

DISCLAIMER: to comply with the New York City Consumer Protection Law which applies to all businesses operating in New York City: We are privately owned mint operated in Brooklyn. We are not a City of New York store , United State Mint nor are the website, products or services affiliated with the City of New York or any agency of the City of New York or federal state agency. We itself, its business, website, products, services, or any hyperlinks from its website are not sponsored by, approved by, affiliated with, endorsed by, or connected to the City of New York or any agency of the City of New York, including but not limited to federal agency , Federal reserve bank, or any Government agency directly or by implication.